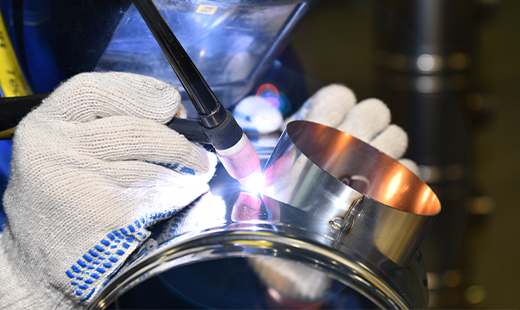

We take over your welding work

Discover the latest welding techniques in our certified company!

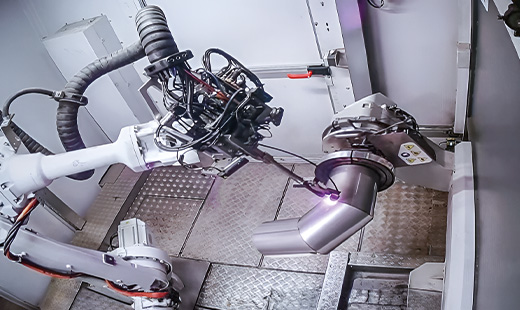

With MIG, MAG and TIG welding, we offer tailor-made solutions for your requirements. Our welding robot also guarantees perfect results in series production. Thanks to our modern and common welding processes, we are able to precisely implement your individual wishes.

Whether it is welding steel, aluminum or other materials, we guarantee the highest quality in execution.

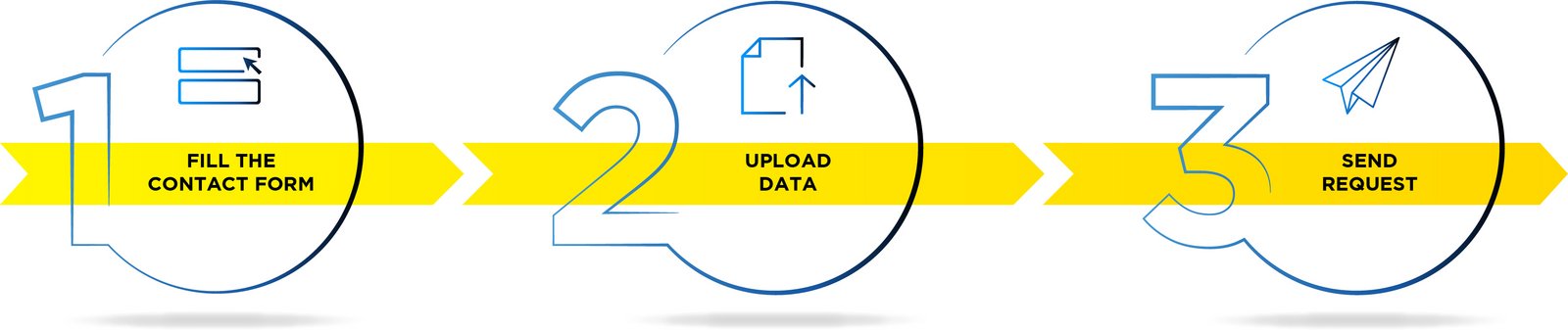

See for yourself!

Certified welding company

We are a certified welding company that places the highest value on quality. We regularly undergo strict audits by TÜV and various chambers to ensure that we can always offer you first-class welding quality and the highest level of professionalism. All welding work is carried out exclusively by experienced and certified welders.

- Welding certificate according to EN 1090-2 (up to and including EXC3)

- EC certificate for factory production control according to EN 1090-1 (up to EXC3)

- Certified according to DIN EN 3834-2

- Certified according to DIN EN 13084-7

Feel free to convince yourself of our expertise!