Breweries

Mash Tuns and their Functions in the Brewing Process

Similar to mills, mash tuns come in various designs. Their primary purpose is to convert starch into sugar through enzymatic processes at specific temperatures. Therefore, good insulation is crucial. Some mash tuns have motorized stirrers, while others have only a large access hatch, requiring brewers to stir the mash manually with a paddle. For those opting for a steam system, a steam jacket is an available feature for mash tuns, allowing for efficient temperature control during the mashing process, but this is only used by breweries that operate their equipment with a steam boiler.

After mashing and filtering the spent grains from the wort, it’s time to boil. There is no better equipment for this task than a brew kettle, which can be heated with various energy sources. The main heating sources currently used in commercial breweries are steam, electricity, and indirect fire (gas). Regardless of the type of kettle you choose, insulation is another important factor, as heat loss can negatively impact the boiling process.

Steam kettles provide the best control and efficiency for heating. They require a steam boiler or generator and a dedicated boiler room. This option is not common for smaller breweries today, but steam kettles are the most popular choice for large breweries due to their efficiency and production capabilities. Electric kettles are gaining popularity but come with their own challenges. Most commercial electric kettles use immersion heaters that are submerged directly into the wort, and the high sugar content combined with the intense heat generated by the elements can lead to scorching. For this reason, it’s essential that immersion heaters in contact with the wort have a low watt density. Indirectly heated tanks use natural gas or propane to power a blower burner. You can think of this blower burner like a 300,000 BTU hair dryer (but definitely something you wouldn't want to stand in front of). It’s mounted to a combustion chamber that is welded under the kettle body, blowing 1000-degree-F air through the chamber and out the flue. These tanks require standard all-fuel chimney pipes to handle the heat from the exhaust, which can be quite costly. However, this is a very common heat source for startups and established breweries due to its ease of setup and the affordability of natural gas in many areas.

A whirlpool is used as the final step on the hot side of brewing before the wort is passed through the heat exchanger. The boiled wort is pumped from the brew kettle into the whirlpool, where it circulates for a time through a tangential opening on the side of the tank. This creates a whirlpool that collects trub or sediment in the center of the tank. The clean wort is then drained through an opening on the side of the tank, which is often protected by a small piece of metal (called a hop dam) to prevent any stray hops added during the whirlpool from entering the drain. This separation process is crucial when using a plate and frame heat exchanger to prevent large solids from clogging it.

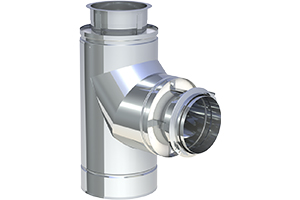

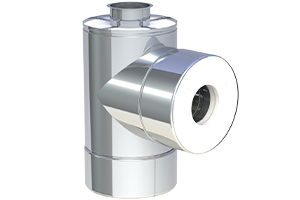

Our Jeremias flue systems feature an outer casing made of 304 stainless steel, ensuring easy cleaning due to its material properties. You can find a selection of suitable flue systems for breweries here.