Industrial bakeries

Industrial bakeries have unique requirements for flue gas systems. Jeremias offers flexible solutions that meet these requirements, including a wide range of products and experienced technical advisors.

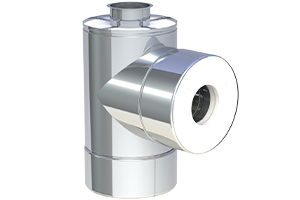

Flue gas systems for baking ovens in industrial bakeries must meet special requirements, as each baking oven typically has four pipe connections: a flue gas pipe, a steam pipe, a fresh air pipe for the oil/gas burner, and a hood duct through which hot air can be drawn off when the oven is opened.

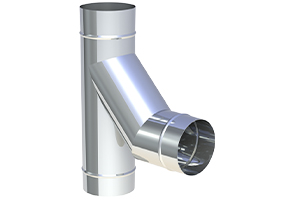

The hot flue gases from the various burners as well as the steam, i.e. the moist exhaust air from the oven, are usually led to a heat recovery system in the form of a cascade system via a flue gas or steam collecting duct.

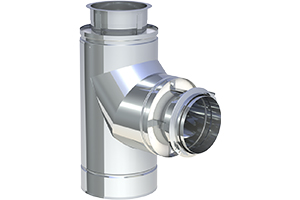

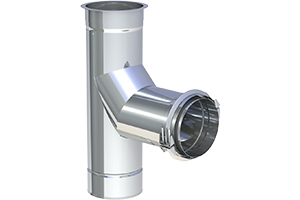

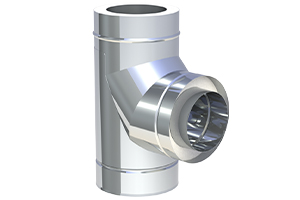

Since steam contains a high proportion of moisture due to the baking process, the tightness of the pipe system is particularly important in this case. The plug connection with an internal special seal and an external clamp band ensures this in the aforementioned Jeremias element systems.

In order to lose as little heat as possible on the way to the heat exchanger, an insulated, double-walled stainless steel chimney is usually installed as the flue gas pipe.

While this flue gas system is also used predominantly in the main chimney, the use of a pressure-tight, single-wall system is recommended for the fresh air and steam ducts.

Jeremias offers flexible solutions for the most diverse requirements and planning designs. Thanks to the largest product range on the market, flue gas systems from Jeremias are compatible with all conveyor ovens, batch ovens, etc. available on the market. Our competent technical advisors have many years of experience in the bakery sector and have already realized many comprehensive and challenging projects.