Coffee roasters

For a good coffee you need the perfectly roasted beans!

The initially raw coffee beans are roasted in special roasting machines. Depending on the roasting process, coffee beans placed in a rotating drum are heated to an internal bean temperature of 752 to 3272 °F. The hotter the raw beans are roasted, the faster large quantities of beans can be refined (hot roasting). The gentler drum roasting takes more time and requires around 752°F. During the roasting process, the desired roasted aromas are created and each bean loses up to 20% of its weight, mainly in the form of oil and water. The released greasy gas must be transported to the outside through a high-temperature-resistant exhaust system. Over time, grease and moisture build up there and increase the risk of fire, which is why regular maintenance and chemical cleaning of the exhaust pipe by specialist companies is mandatory.

In order to keep the pipe system tight during the cleaning process and to avoid unpleasant odors in the installation room, the use of a pressure-tight exhaust system is necessary. This is even more true if the roasting machine has an integrated fan. However, systems with conventional silicone or EPDM seals cannot be used here, as these could be damaged due to the sometimes high temperatures of the exhaust gases.

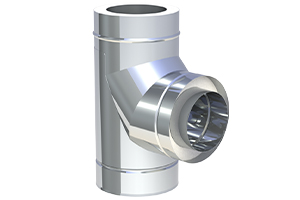

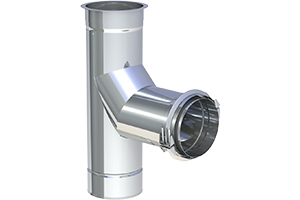

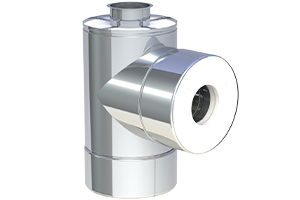

A clear case for our stainless steel exhaust system DW-KL, which is pressure-tight up to 0.73 psi with its metallic conical plug connection. As a double-walled exhaust system, it also has mineral insulation between the inner and outer pipes, which reduces the temperature emission and noise transmission to the installation room.