Chimney relining

And with the chimney everything is in balance!

If the existing house chimney shows signs of wear due to age or no longer meets the requirements of a modern heating system, a chimney renovation is necessary.

How does the wear and tear come about?

Due to years of firing in brick chimneys, dirt particles and acidic condensate penetrate the walls. Since the chimney cross-section is usually too large for the low exhaust gas temperatures of modern heating systems, the water vapor from combustion in the fireplace or pellet stove condenses and condensate forms inside the chimney. These acidic substances penetrate the masonry of the chimney and severely attack it. From this moment on, the brick chimney gradually rots away. The stains of sooting are not only unsightly, but also very dangerous, since the house chimney is eaten away and can even attack the masonry of the building. Another risk for the house chimney is the deposit of soot. In this case, too, chimney renovation is recommended. A lot of soot forms on the walls due to deposited soot particles. This soot formation is caused by irregular cleaning, overloading of the stove or incorrect operation.

Where is the risk of soot formation?

The soot collected in the walls of the old chimney can heat up so much when it is fired that it catches fire. This event is called a soot fire. You can recognize it by the strong flying sparks and flames blazing from the chimney.

What can be done against chimney sooting?

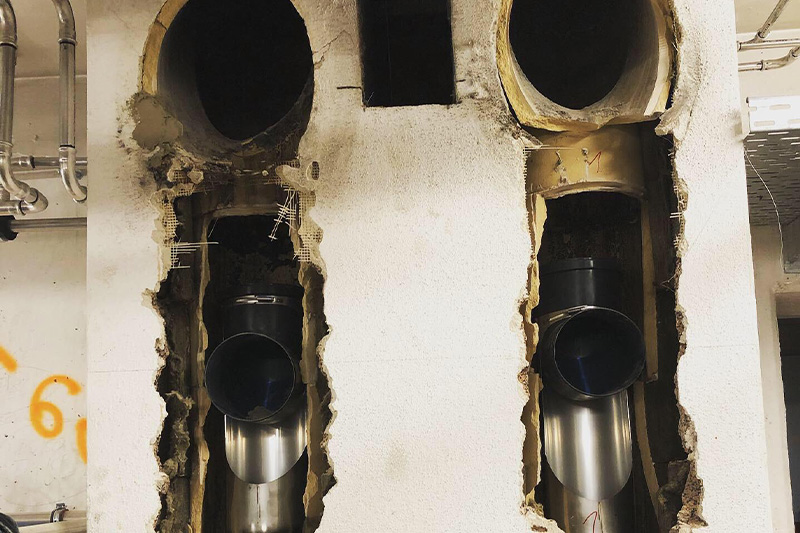

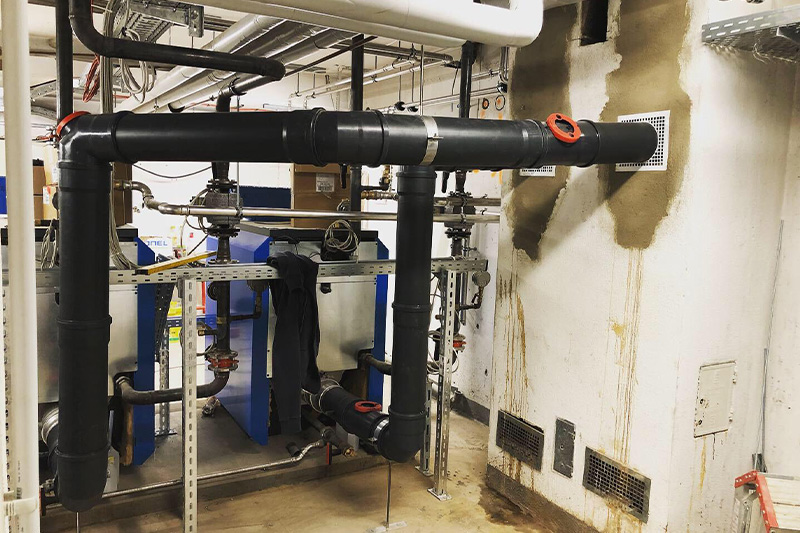

The best way to counteract the sooting is to install single-walled flue gas systems, the so-called chimney renovation. The kits made of stainless steel or polypropylene (plastic) are ideal for cladding the brick chimney from the inside. The individual elements can be simply plugged together and inserted into the existing chimney from the chimney head. Simple assembly using precisely fitting elements and plug-in connections makes work a lot easier. Due to the flexible systems and angles, obstacles are not a problem and can be compensated.