MED-GA

Motorized exhaust dampers

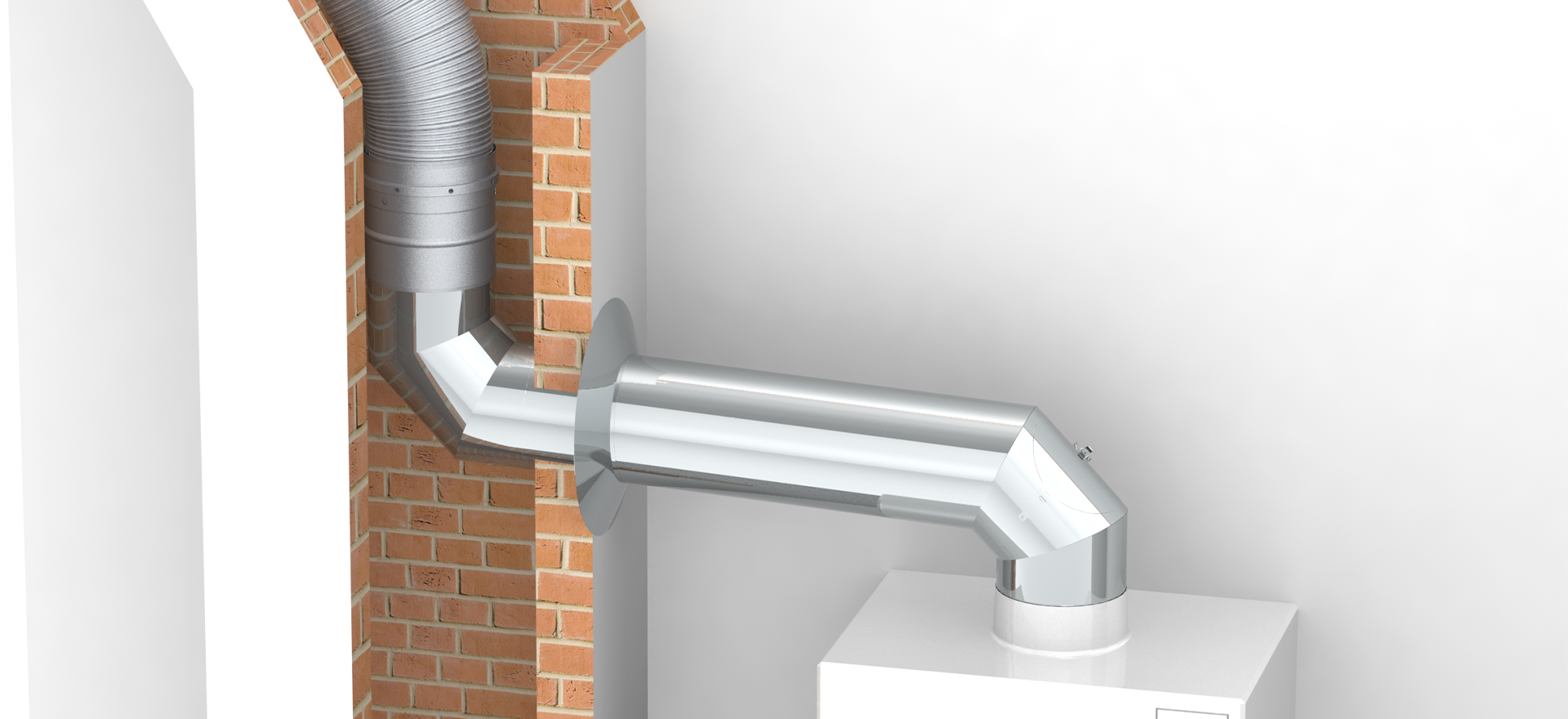

Motor actuated gas vent damper for overpressure applications with wet exhaust conditions (Category IV Appliances). Reduction of cycle venting losses through boilers and draft hoods.

A motor-controlled flue gas damper is suitable for installation in the exhaust systems for all standard appliances which are fired with oil or natural gas. During standstill periods of the appliance, the damper (flap) automatically closes the exhaust path preventing loss of heat. When the temperature controller needs heat, the electric motor automatically opens the shut-off flap before the burner starts and the program of the burner control unit is enabled.